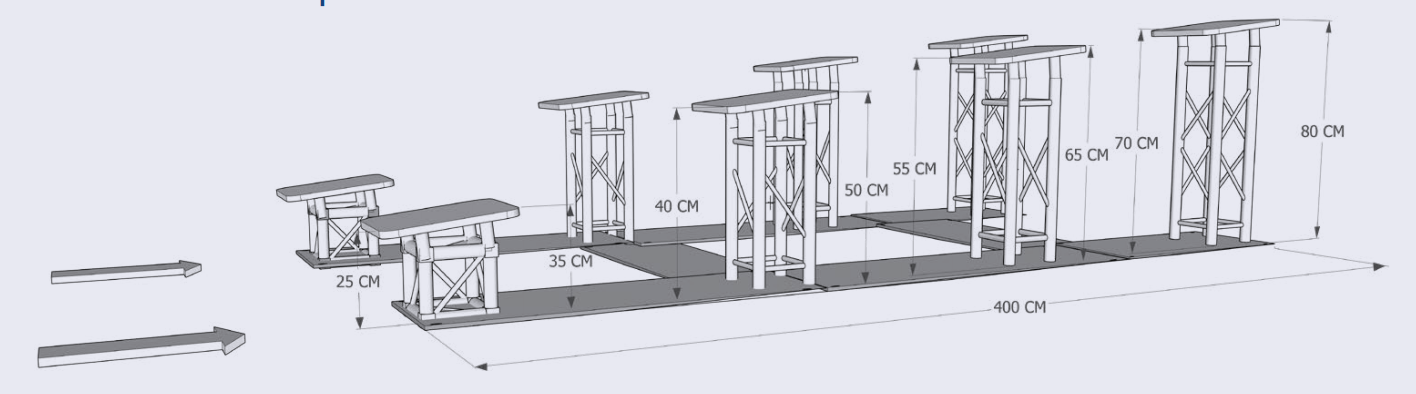

Steps + Fall mat

Crossing

Traverse the steps with the feet. Grasping or touching

the steps with the hands is forbidden.

Characteristics

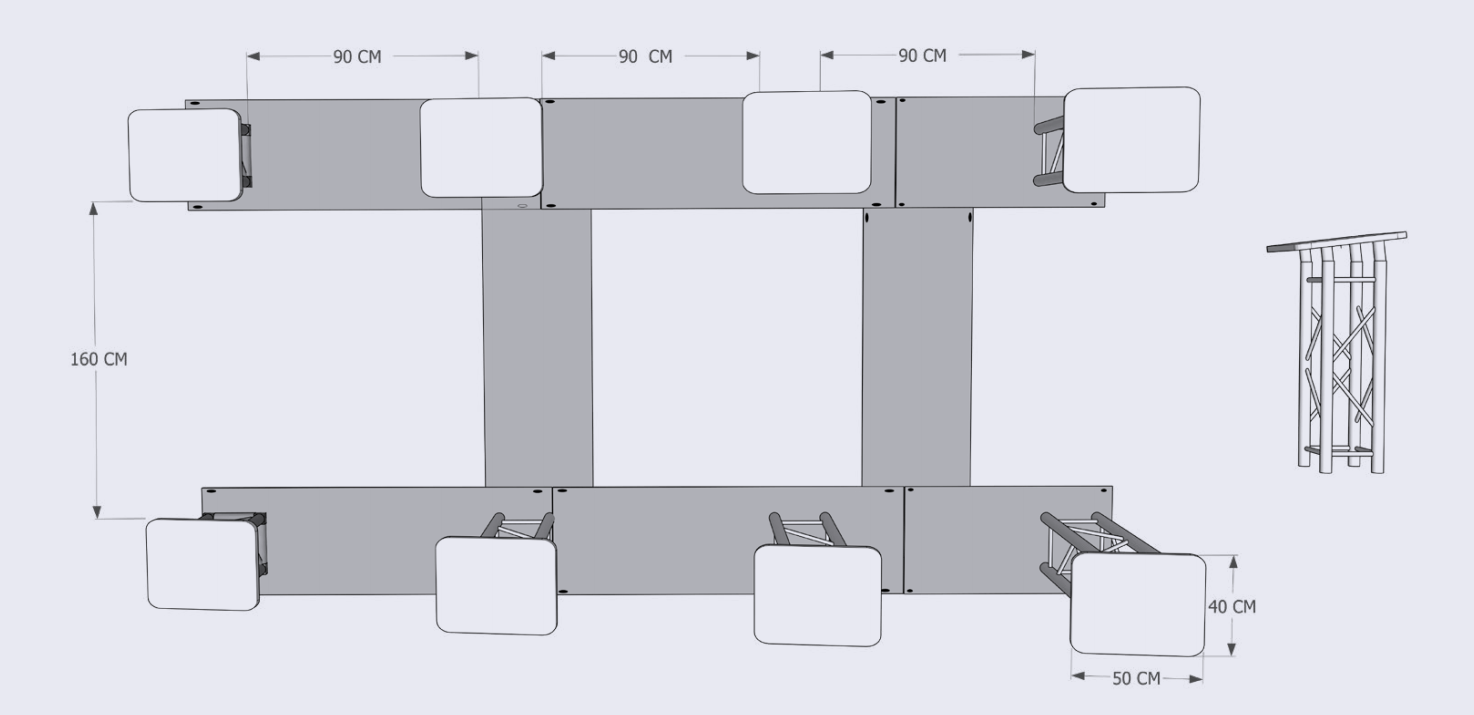

Length…………………………………………………..400cm (+/-10cm)

Lateral elements spacing………………………………………..160cm

Steps spacing* …………………………………………………………. 90cm

Step base……………………………………………………..30cm x 30cm

Step top …………………………………………………….. 50cm x 40cm

Steps height (lower part-upper part)**

– First step…………………………………………………… 25cm-35cm

– Second step ……………………………………………..40cm-50cm

– Third step…………………………………………………. 55cm-65cm

– Four step…………………………………………………..70cm-80cm

*Measured between the bases of the steps.

**General tolerance +/-0.25cm

What is UIPM Obstacle?

Obstacle is a brand new feature of our sports portfolio and will soon be unveiled as a discipline of Modern Pentathlon and a standalone UIPM Sport.

Obstacle was formally integrated into Modern Pentathlon by the 72nd UIPM Congress in November 2022, having been selected by the New 5th Discipline Working Group as the most suitable replacement for Riding after the Paris 2024 Olympic Games.

The sport was the overwhelming favourite of more than 60 proposed to propel Modern Pentathlon into a new era and make it one of the most exciting, accessible and popular sports in the Olympic movement.

The term ‘Obstacle’ encompasses various types of obstacle racing across the categories of Ninja, OCR and Adventure Racing.

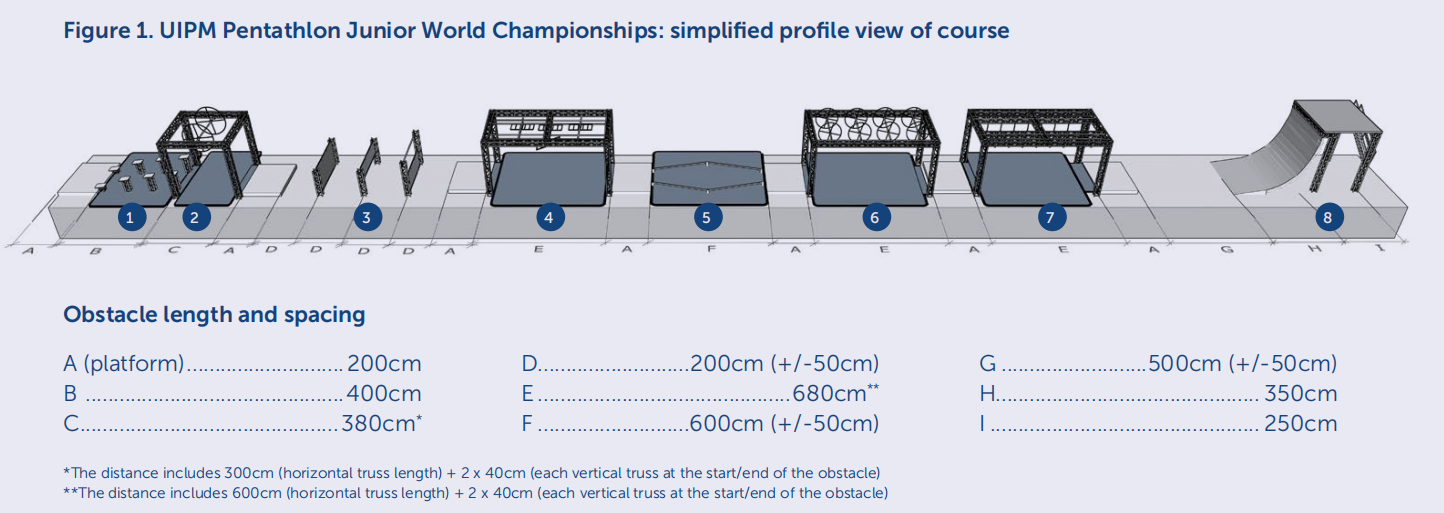

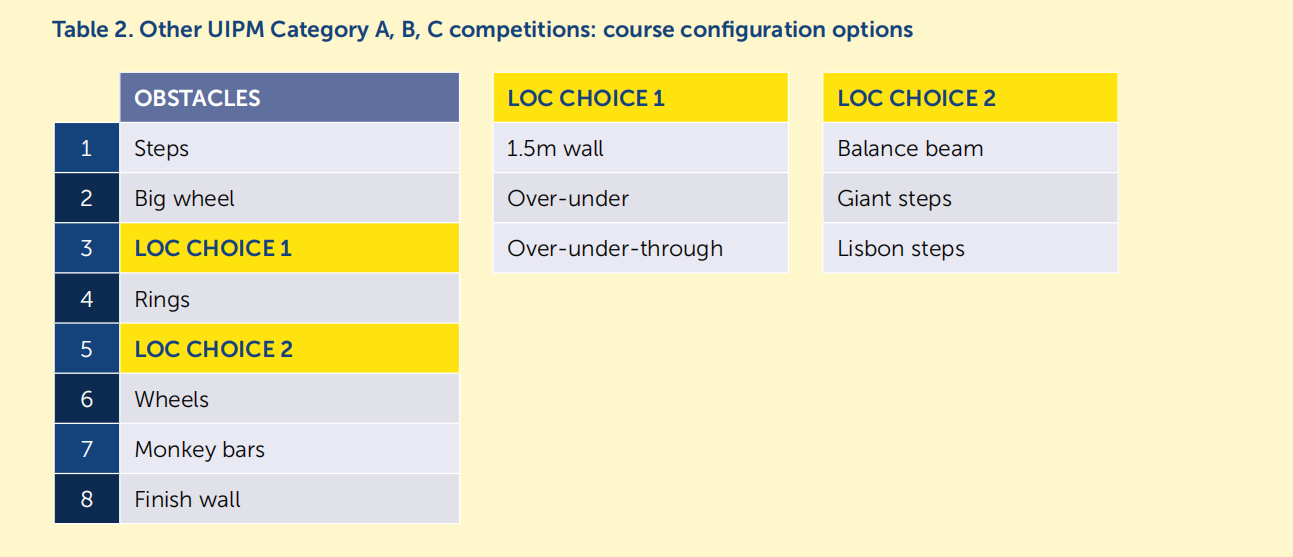

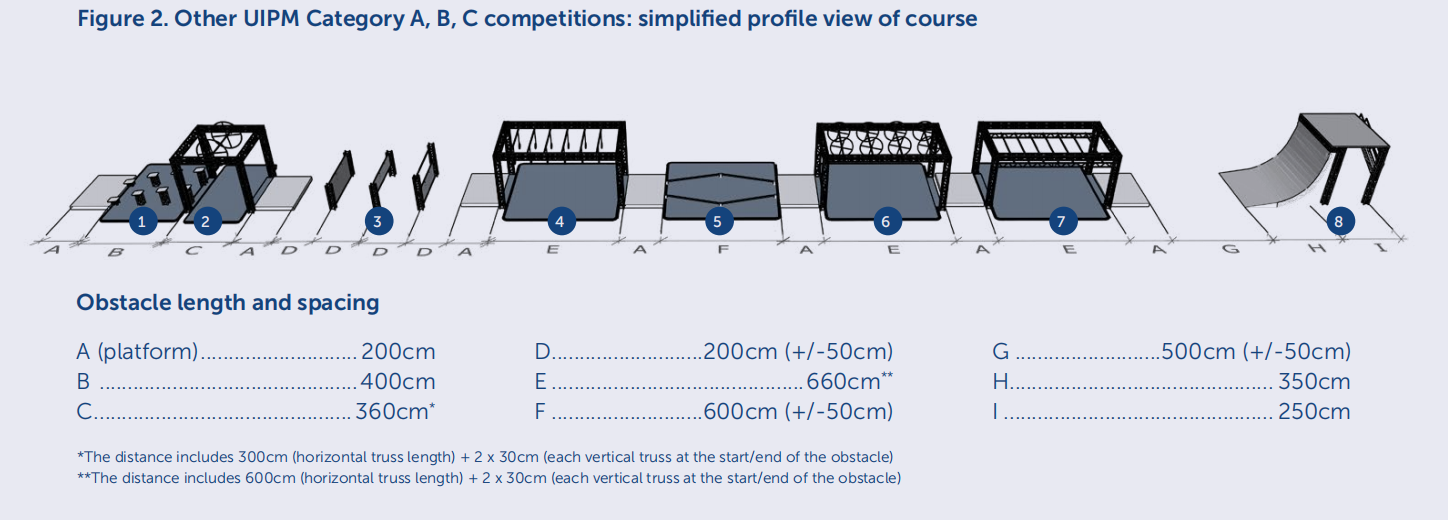

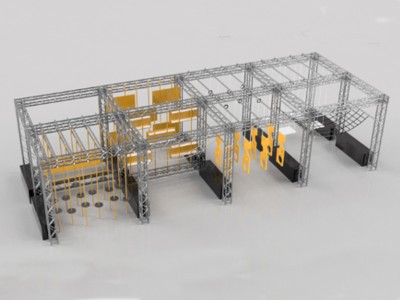

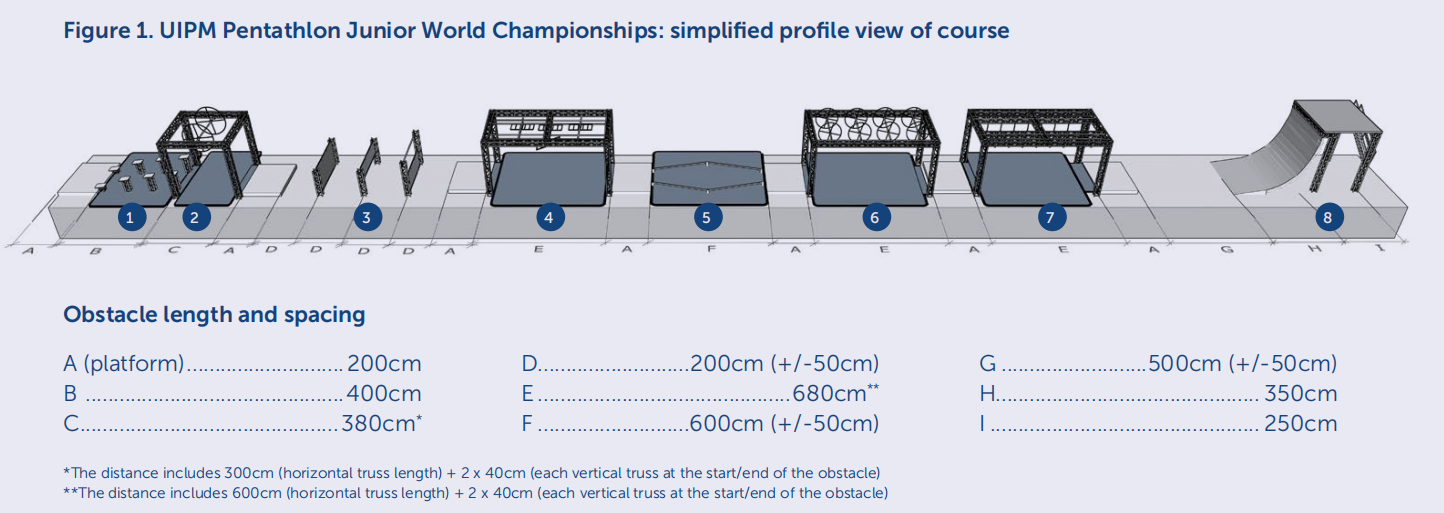

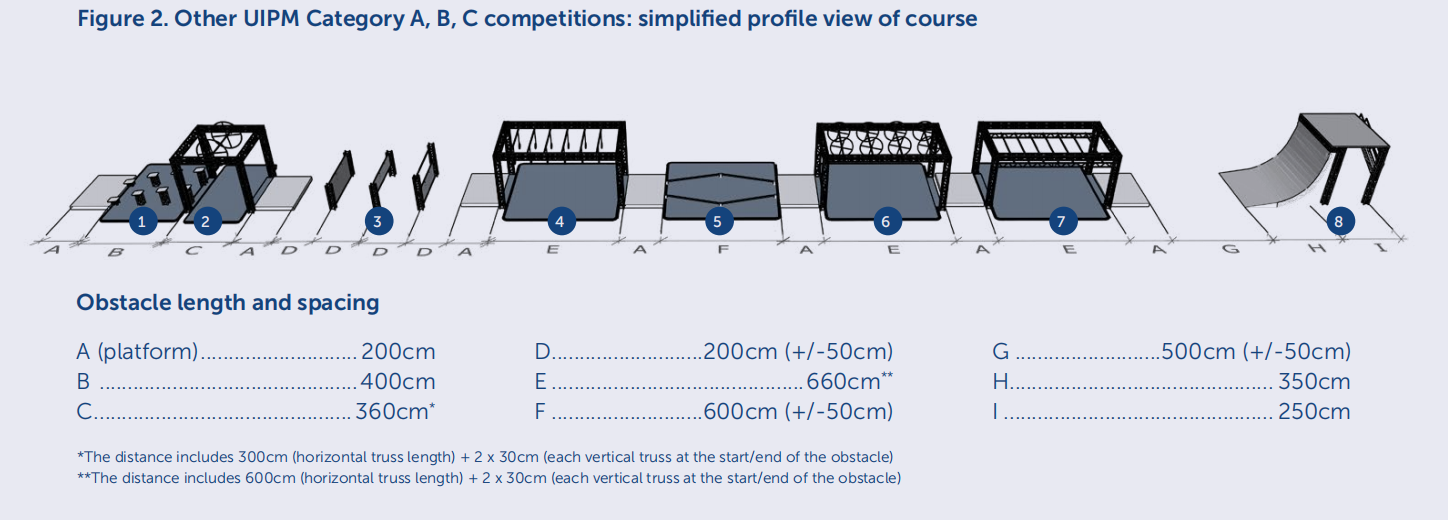

This section contains the general course regulations for various events. No matter the level of the event

or the flexibility to be applied to its organisation, the course set-up will always consist of eight obstacles

over a 60m-70m distance for both individual and relay competitions.

The length of the course is a horizontal distance measured along the centreline of a lane from the

vertical plane of the start line to the vertical plane of the finish buzzer centreline, with the athletes

competing in two lanes.

The course can be set on a straight line, curve, or “u”/ “v” shape. The examples shown on the figures

above mentioned refers to a straight-line course.

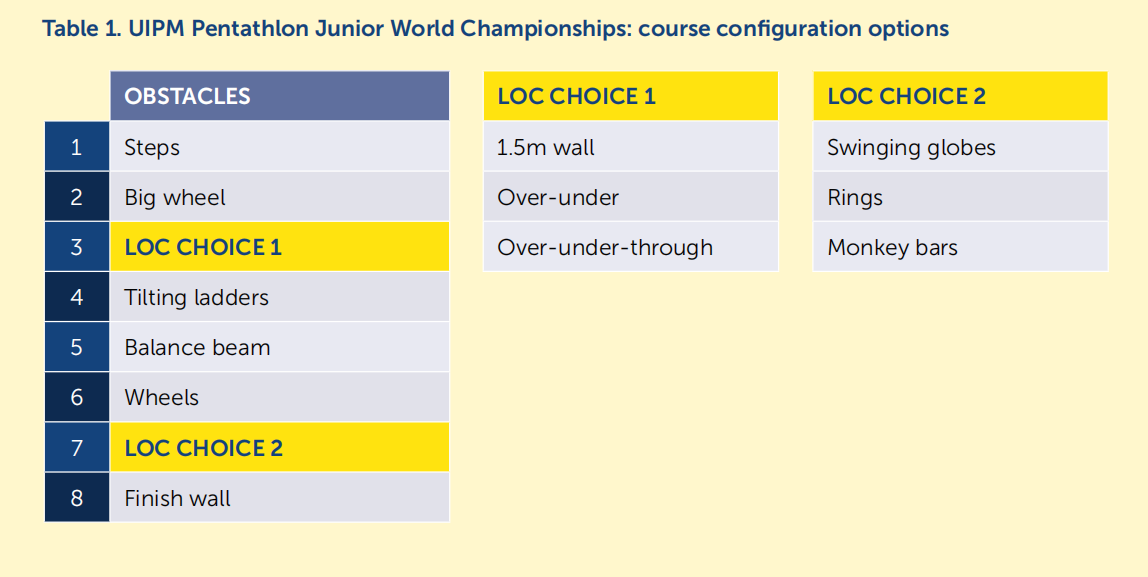

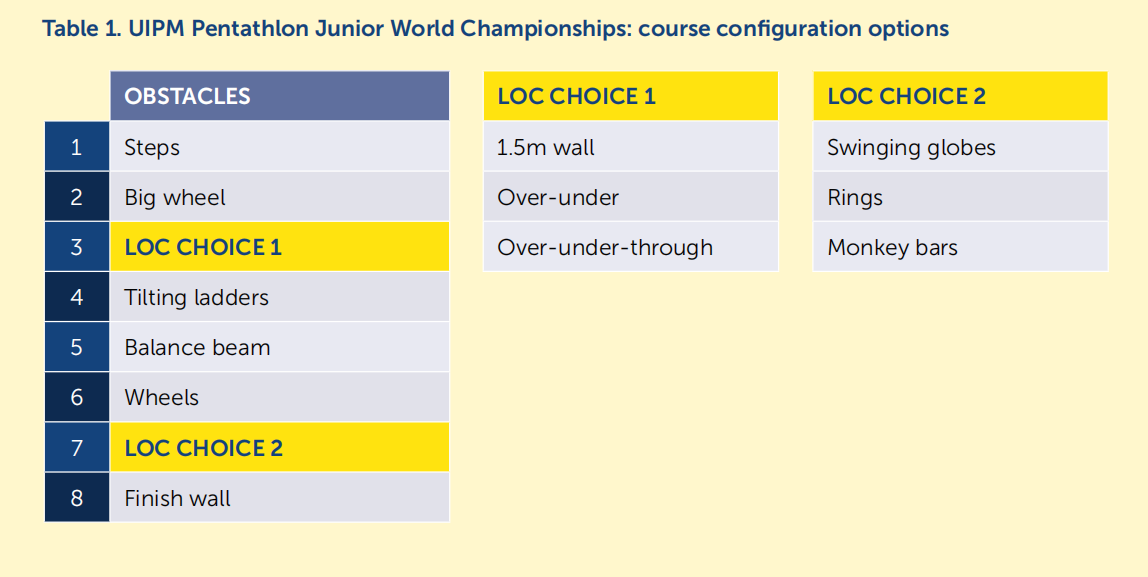

In the UIPM Pentathlon Junior World Championships, six of the eight obstacles on the course are fixed

by UIPM, while the competition Local Organising Committee (LOC) can select the other two obstacles.

The configuration of the course must be according to Table 1. Obstacles 3 and 7 in the first column

shall be chosen by the LOC from the three options available in the adjacent columns. The LOC choices

must be communicated in the competition invitation letter.

In the UIPM Pentathlon Junior World Championships, platforms must be installed before and after each

obstacle according to Figure 1 with mattresses covering all areas where a fall from height can happen.

The course must be set on an elevated structure. The height of the running surface must be constant

with a minimum of 40cm and a maximum of 100cm from the ground. Structural components may be

wider and higher than those described in section 3 of this catalogue to adapt the construction of the

obstacles to the elevated structure. Regardless, the obstacle characteristics described in each section

will remain the same, while maintaining standard obstacle functionality.

In Figure 1 a simplified view of the course is presented with obstacle 3 choice “over-under-through”

and obstacle 7 choice “swinging globes”.

Platforms must be installed before and after each obstacle according to Figure 2 with mattresses

covering all areas where a fall from height can happen.

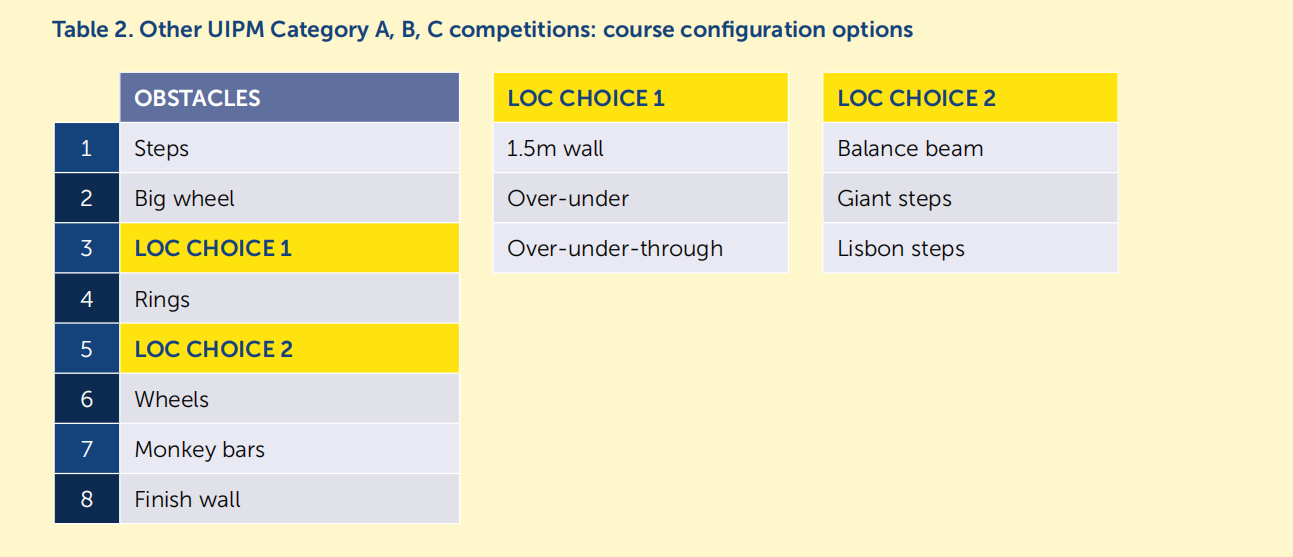

With the exception of the UIPM Pentathlon Junior World Championships, all Category A, B and C

competition courses can be built with obstacles set directly on ground level.

In Figure 2 a simplified view of the course is presented with obstacle 3 choice “over-under-through”

and obstacle 5 choice “balance beam”.

Other competitions

LOCs can have more flexibility in Category B and C competitions for U17, U19 and Junior age groups

(beneath UIPM World Championships level). But where this flexibility is applied, as explained below,

no Pentathlon World Ranking (PWR) points will be granted.

Changing the order of the obstacles is allowed, but modifying their dimensions is not permitted,

to ensure the consistency and safety of the competition. Obstacles not listed in this catalogue

cannot be used. Using materials other than trusses will be allowed to build structural components

provided the materials and construction methods meet all safety requirements presented

in this catalogue.

Instead of platforms before and after each obstacle, a line can be marked on the ground (or on the

safety mattress) clearly indicating the beginning and the finish of each obstacle.

For national competitions, LOCs are given the flexibility to make changes to the obstacle course design.

However, the basic structure of the course – eight obstacles and 60/70m in length – must remain

consistent. It is important to stress that any obstacle with a structural element must be built according

to a qualified professional-approved design. The LOC must always be sure the course is designed and

built for minimum risk1 and its level of difficulty is adequate for competitors.

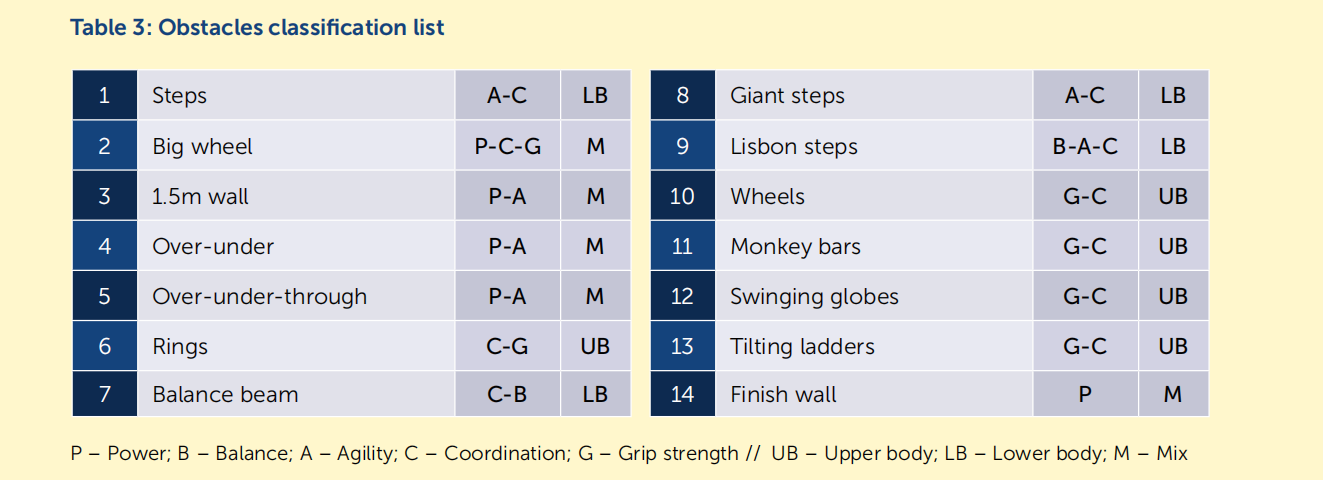

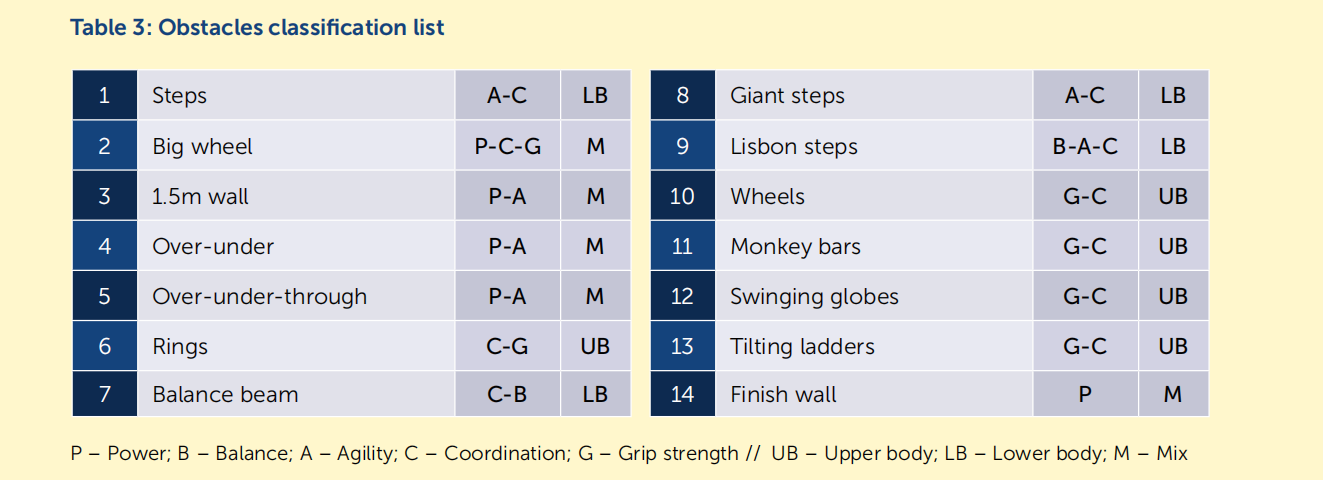

Obstacles classification

The obstacles presented in the courses in section 1 were divided into five simplified categories. These

categories were determined。

•Power

The ability to exert maximum force through a move as quickly as possible. The two components of

power are strength and speed.

•Balance

Postural control both moving and stationary.

•Agility

The ability to perform sudden movements in quick succession and in opposite directions.

•Coordination

The ability to execute smooth, accurate, controlled movements, including hand-eye

coordination and gross motor skills.

•Strength (grip strength)

The force applied by the hand to pull on or suspend from objects; a specific part of hand strength.

Table 3 provides the list and classification of obstacles by categories, as well as the specific body

segment involved in their successful completion.

Structural components

a) UIPM competitions

The architecture of obstacles is an essential part of the course to maintain long-term consistency across

competitions and ensure the safety of athletes. The technical specifications for the obstacles, including

their dimensions and structural integrity, are outlined in section 3.

In UIPM competitions, the structures used are of the truss type, with a square cross-section.

The dimensions for these structures vary depending on course characteristics and competition level.

For the UIPM Pentathlon Junior World Championships, the trusses square cross-section shall measure

40cm x 40cm and 2mm wall thickness. This provides more rigidity and stability to accommodate the

increased obstacle heights. For other UIPM competitions, the trusses square cross-section dimensions

can be set at 30cm x 30cm. These dimensions are mandatory to ensure the safety of the course.

The standardised truss structure to be used in UIPM events is made in 6082 Aluminum alloy with TUV

Homologation. It is chosen for its high strength-to-weight ratio, durability, and ease of assembly,

making it the ideal choice for temporary structures that need to be set up and taken down frequently.

Additionally, the square cross-section allows for a greater degree of flexibility in terms of layout.

To ensure safety and stability of structural components of rings, wheels, monkey bars, swinging globes

and tilting ladders, in UIPM events only 600cm long trusses will be accepted. Therefore, two segments of

300cm each will not be allowed.

When building obstacles using trusses, all load calculations must follow the norm UN-ENV 1999-1-1

(Eurocode 9).

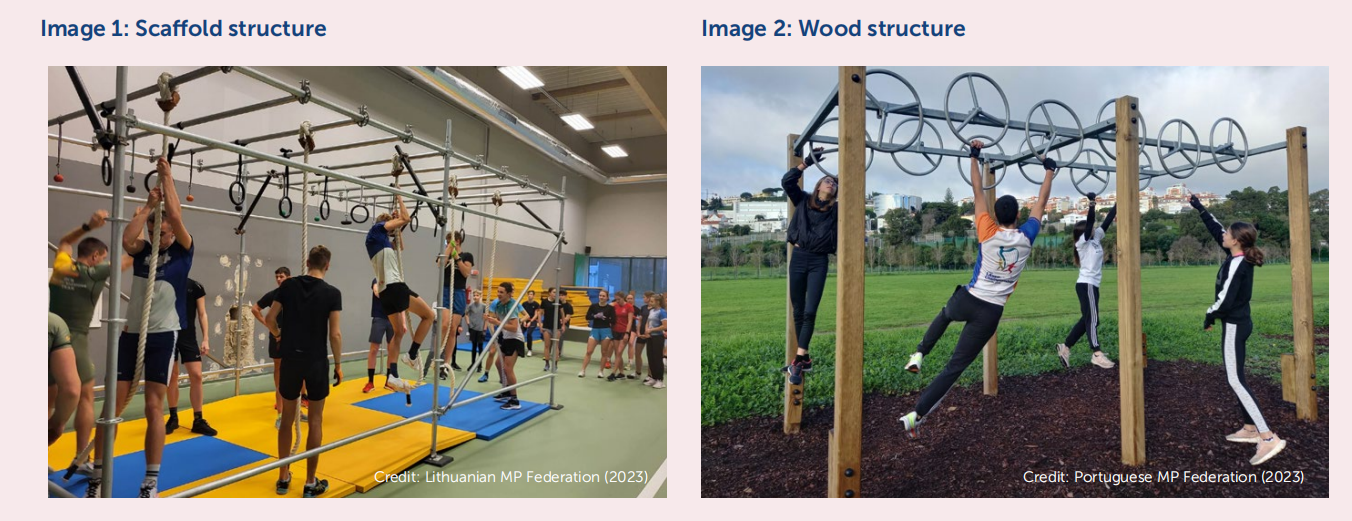

b) Other competitions

A variety of materials such as steel trusses, scaffolds and wood, among others, can be considered when

constructing obstacles. Using simpler and more efficient construction methods, such as prefabrication or

modular construction, can reduce costs while maintaining safety standards.

Using alternative materials or methods should be done under the guidance of a qualified professional

to ensure the safety and integrity of the structure under repeated loading conditions. Athlete safety should

be the top priority when constructing any structure, and it is important that all used materials

and methods meet safety standards.

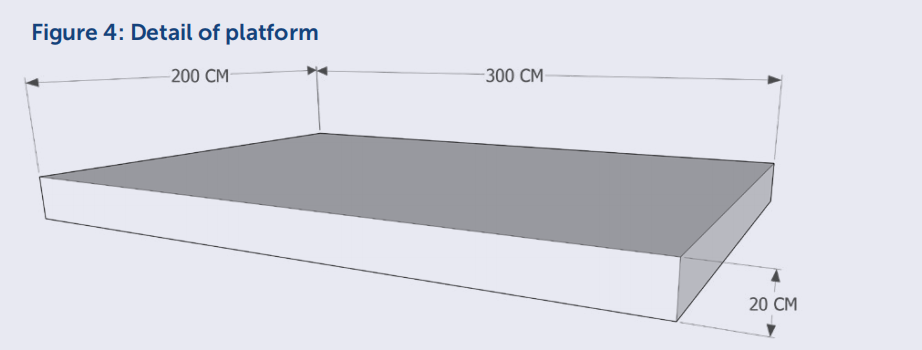

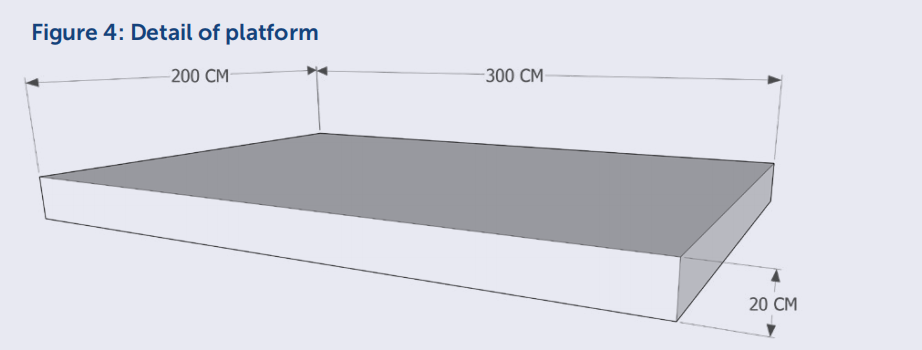

c) Platforms

The platforms described in this catalogue are designed to mitigate the impact load on the athletes and

make the course faster and easier to judge for referees.

Platforms can be constructed using materials such as wood, metal and plastic and should always be

covered with a firm mattress to ensure a non-slip surface and provide a

secure footing for take-off and landing.

Maintaining the platforms properly is crucial to ensure the surface remains smooth and free of hazards

throughout the competition.

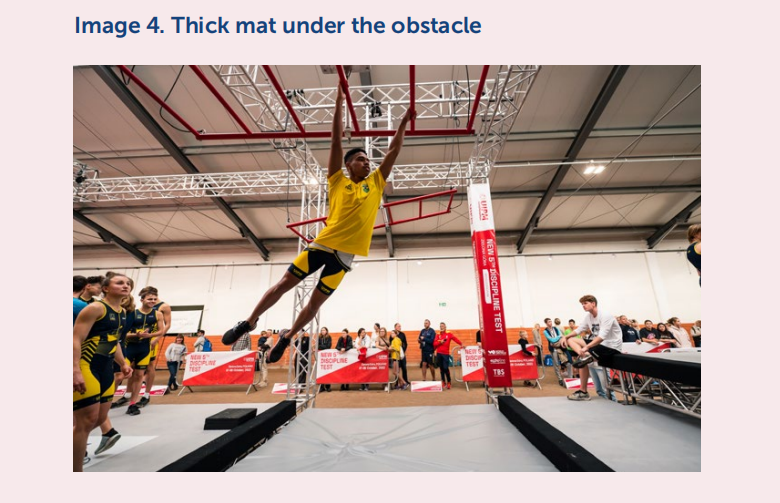

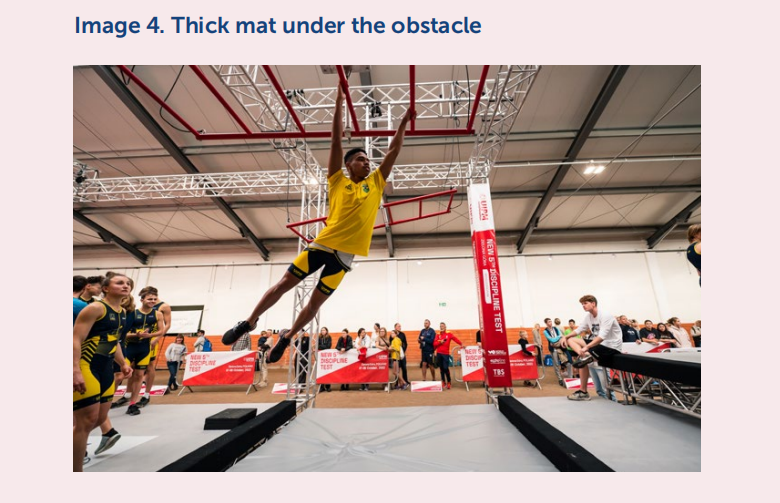

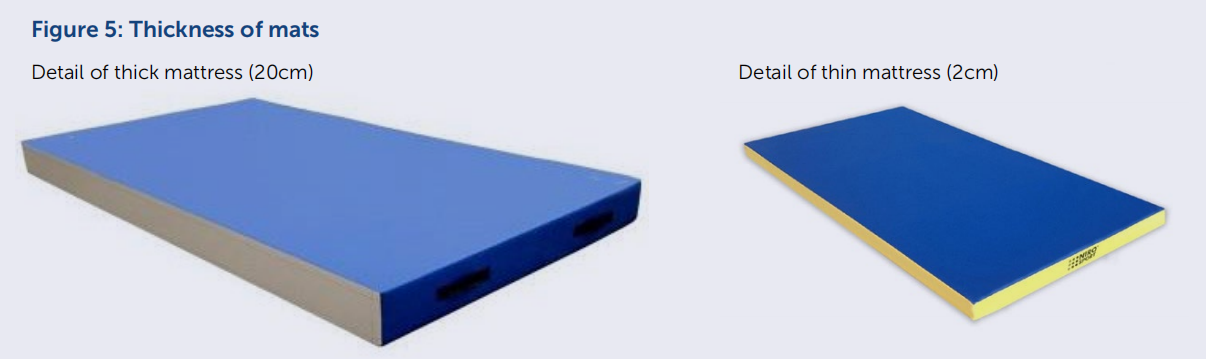

d) Safety mattresses

Correct positioning of the safety mats is essential for the safety and security of participants. The mattresses

should be placed in a manner that minimizes the risk of injury to athletes while they are traversing the

obstacle course.

Thick mats must fully cover the surface under the obstacle and extend beyond its boundaries by a minimum

of 100cm on each side, to provide impact attenuation for the athletes in case of a fall from height. Thin, firm

mattresses should be placed on the landing platforms, providing an extra layer of protection for the athletes

and a softer landing surface.

Thick mattresses should not have space between them and adjacent structures (e.g., trusses). Gaps can

create a tripping or entrapment hazard and increase the risk of injury.

The mats must be designed with a high degree of slip resistance (non-slip surface) to provide secure

footing. The core of the mat should be composed of a high-quality composite foam with minimum density

requirements presented below. It reduces the risk of injury while increasing the athlete’s ability to self�

regulate and stabilise their landing. Mattresses should be frequently examined for signs of damage or wear

and, where appropriate, repaired or replaced.

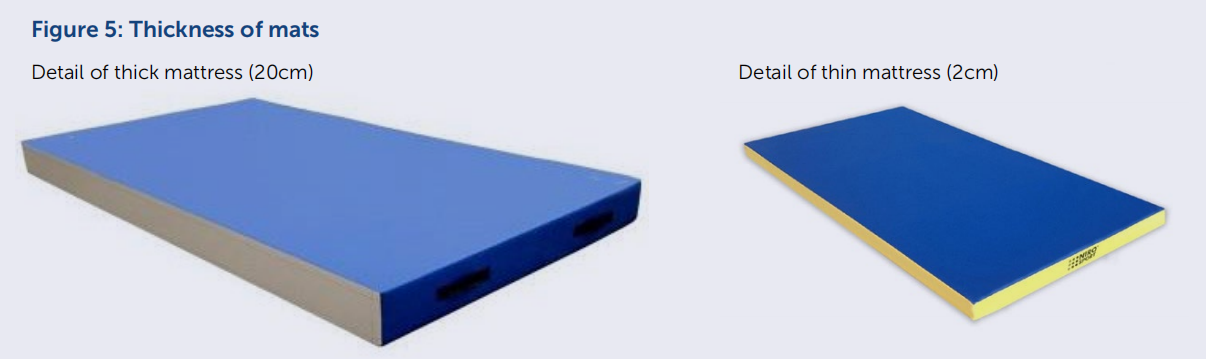

Two thicknesses of mats shall be used for this purpose:

•

Thick mat must cover the entire surface under each obstacle and extend beyond the boundaries of

the obstacle by at least 100cm on each side. The mat should be at least 20cm thick – the same as the

adjacent platforms – with a recommended density of RG25 (25kg/m3).

•

Thin mat should be placed on the landing platforms to enable a softer landing. The mat should be 2cm

thick with a recommended density of RG20 (20kg/m3).

Each obstacle includes a start line or take-off platform and a finish line or landing platform so it can be

considered successfully completed.

The conditions for correct completion of an obstacle are as follows:

a. Start line: The athlete must start the obstacle with both feet before the line marked on the ground.

Touching the line with any part of the body is considered a failure.

b. Finish line: The athlete must land with both feet beyond the line marked on the ground or mattresses

under the obstacle. Touching the line with any part of the body is considered a failure. Falling or stepping

backwards on or before the line is considered a failure.

c. Take-off platform: The athlete must start the obstacle by taking off from the platform. Falling or

stepping forward off the platform is considered a failure.

d. Landing platform: The athlete must land only on the platform. Falling or stepping backwards off the

platform is considered a failure.

Previous: Obstacle Course Racing UIPM Obstacle 2. Big wheel

Next: Spartan Race Obstacles Single Thigh Master attempt obstacle ADDUCTOR

1. Why your factory provide not only lighting truss, but also flight case, portable stage, pipe and drape ,ect ?

Actually, the reason is very simple. All our product need the similar raw material , like plywood, aluminum alloy tube. We just need buy the professional machines, hire the skillful workers and enhance the R& D Team. We hope we could provide “ One-Stop service” for our clients.

Our concept is “ Tourgo , Build your dream” Our goal is to win the bright future and be the No. 1 Pro sound & Light equipment manufacturer.

2. Does Tourgo company provide the OEM service?

Yes, Tourgo could provide the OEM service according to your request.

We have the ten-year designers team, the customized flight case, portable stage, and lighting truss also is available, just need your idea!

3. Does Tourgo company offer warranty for the sold products?

Only if your products are purchased from Tourgo company, we promise life time warranty. In other words, if your products are purchased directly from us or our dealers, you can enjoy such warranty.

4. Do you provide the flight cases parts for replacement I purchased from Tourgo company ?

Well, almost all our flight cases parts are replaceable. You can replace them yourself. If you want to get them, you can contact us soon.

5. What is the mean of Alphabet “U” in rack case catalog?

For rack case, we offer 2U, 4U, 6U, 8U and other models of “U” cases. “U” here is a unit referring to inner height of the rack case . Usually, 1 U equals 1.75” (4.45cm).

6. I want to distribute your products in my country. How can I become a distributor ?

Tourgo has searched global deals for all our products. We will provide preferential offers for all deals, especially those in large amount. For most information about dealership, please visit our Distributor Wanted.

7. What is the MOQ for your products?

Tourgo requires no minimum order quantity, and we can ship single item samples or large orders worldwide for any clients who are in need of our products

8. Can I get any discount for my order?

Yeah, you can contact our sales team, depending on the amount of your order

- The products you need

- The exact desired order quantity

- Your desired time frame

- Any special packing instructions

With this information we will get back to you with a quotation.

We also offer limited time promotion, please notice our post in our website.

9. What is your payment term, delivery time? Do you have the reliable freight agent?

The payment term is T/T, Western Union.

Delivery time is 7 – 15 days after we get the payment. Surely, if you need the goods urgently, we try our best to meet your demand. Moreover, we will send your goods pictures to you before the shipping

Yes, as a leading manufacturer, we have the reliable freight agent and has done the business with them for many years. If you have your own agent, we would like to coordinate with them fully.

10. Will you send the drawing of the custom product for our confirmation before the production?

Yes, Absolutely! Like custom flight case, lighting truss project, portable stage project. We will provide the professional drawing for your confirmation before our production.